English

French

Italian

Portuguese

Spanish

In today’s world, industries are facing increasing pressure to find sustainable solutions for managing their effluents and waste streams. Evaporation concentration systems have emerged as a reliable and efficient method for treating various types of effluents and liquids. These systems not only help in reducing the volume of waste but also enable the recovery of valuable byproducts. In this article, we will explore the different types of evaporation concentration systems and their applications, highlighting their role in promoting efficiency, sustainability, and environmental stewardship.

Evaporation concentration systems come in various configurations to suit different applications and fluid characteristics. One such system is the corrugated tube evaporator, specifically designed for low viscosity effluents with reduced particle size. The K Series heat exchanger, used as an evaporator module in this system, offers high heat transfer efficiency and excellent resistance against fouling. Some common applications of corrugated tube evaporators include:

In certain applications where the risk of fouling is high and the fluid exhibits elevated viscosities, scraped surface evaporators provide an effective solution. HRS recommends the Unicus Series as an evaporator module for such high fouling fluids. The self-cleaning scraper action of the Unicus Series ensures efficient heat transfer and minimizes the risk of fouling. Some common applications of scraped surface evaporators include:

Evaporation concentration systems are designed to maximize energy usage and minimize environmental impact. Two common technologies used for this purpose are multi-effect evaporation (MEE) and mechanical vapor recompression (MVR) or thermal vapor recompression (TVR) systems.

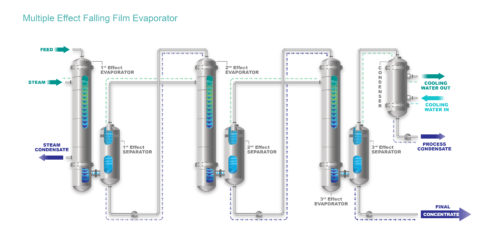

Multi-effect evaporation systems utilize multiple evaporation stages to reduce energy consumption. In these systems, the vapor obtained from a previous stage serves as the thermal energy source for the subsequent stage, reducing the overall energy requirements for water evaporation. By harnessing the synergy between multiple stages, multi-effect evaporation systems offer significant energy savings.

MVR and TVR systems operate by recycling energy within the evaporation process. In MVR systems, the evaporated steam is compressed, increasing its pressure and temperature, and then used as the thermal energy source for evaporation. This setup requires only electrical energy to drive the compressor, making it highly energy-efficient. In TVR systems, boiler steam can be mixed with the evaporated steam in a thermo-compressor, leading to substantial energy savings. Both MVR and TVR systems contribute to the overall sustainability and energy efficiency of evaporation concentration systems.

Evaporation concentration systems find applications across various industries and sectors. Some common areas where these systems are utilized include:

Evaporation concentration systems have emerged as a sustainable and efficient solution for managing effluents and waste streams in various industries. From corrugated tube evaporators to scraped surface evaporators, these systems offer versatile and reliable means of treating different types of effluents. By harnessing the power of multi-effect evaporation and vapor recompression technologies, evaporation concentration systems maximize energy efficiency and minimize environmental impact. As industries strive for sustainability, these systems play a crucial role in achieving efficient effluent treatment, wastewater management, and resource recovery. Embracing evaporation concentration systems is not just a step towards compliance with regulations but a commitment to a greener and more sustainable future.

--END--