English

French

Italian

Portuguese

Spanish

A rendering factory is a facility that turns animal waste into items like fertilizer or animal feed. The term “rendering” describes several procedures, such as high-temperature and pressure cooking that transform slaughter waste and dead animals into fat and meat meals that may be utilized in other products. Around the world, corpses from farms and slaughterhouses are disposed of in rendering facilities. They are also prevalent in certain sizable hatchery facilities where they perform safe processing on poultry that has not hatched or been culled.

The Rendering Plant near me to your home, which makes it a regular concern in the area. You can’t breathe fresh air at home since the rendering plant’s odour is overpowering. Your family, friends, and neighbours could find it annoying. By transforming trash into usable products like soap, fertilizer, and other pet food items, the rendering plant serves as a service to you. Due to its offensive smell, it should be placed away from populated places.

Most of these issues can be resolved in the Rendering plant near me by utilizing top-notch Sunrise tools and gear.

Animal rendering plants are crucial to the effective and long-lasting utilization of animal byproducts. Rendering plants promote manufacturing goods while reducing waste by turning raw resources into valuable items. Collection, preparation, cooking, separation, and final processing are some of the processes that make up the rendering process. Each step is thoroughly controlled to guarantee the end goods’ quality and safety.

The first step in the rendering process is the collection of animal by-products, which can include: * Meat and bone meal * Poultry meal * Blood meal * Feather meal * Animal fat, * Used cooking oil. These materials are gathered from various sources, including slaughterhouses, meat processing plants, restaurants, supermarkets, and farms. The materials are transported to the rendering factory in sealed containers to prevent contamination.

When the materials are delivered to the rendering factory, they are unloaded, sorted to remove any foreign objects like rocks, metal, or plastic, and then ground or shred to reduce their size and increase their surface area, which facilitates the extraction of valuable components during the rendering process.

Cooking comes next in the rendering process. The materials are shredded or pulverized before being put into digesters, which are big steam-heated tanks. For many hours, the components are cooked under intense pressure and heat. The proteins and lipids are separated from the solid components via this procedure, which also breaks them down into smaller molecules. “Rendering broth” is the term for the liquid created while cooking. This broth includes minerals, proteins, and lipids in many products, including pet food, animal feed, and biofuels.

A centrifuge separates the combination of particles and liquids after cooking. The fats and oils are separated from the solids using this procedure. The fats and oils are processed further to improve their purity and eliminate contaminants. “Meat and bone meal” or “feather meal” refers to the solids left over after separation. These substances are utilized in animal feed as a source of protein.

The transformation of the various materials into their finished forms is done at the rendering process’s last stage. Refining and purifying the fats and oils eliminates any residual contaminants. These components are utilized in several goods, including biodiesel, pet food, and animal feed. A fine powder is created by drying and grinding the meat, bone, and feather meal. After that, these components are packed and offered for sale as a source of protein for animal feed.

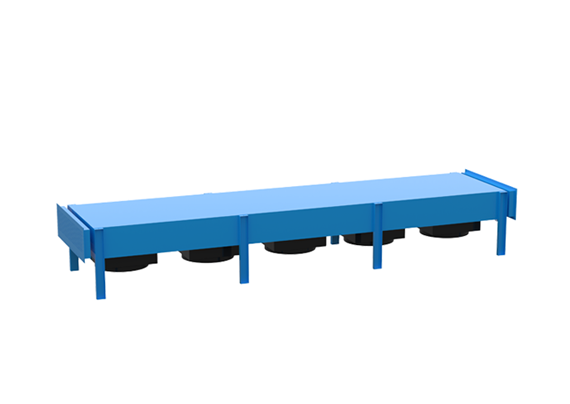

SunRise is a well-known manufacturer of rendering plant equipment in China, with a sizable production base and an established technological infrastructure. It has always been committed to offering consumers top-notch rendering plant equipment and services. We make it a point to develop top-notch, long-lasting items that will serve you well for many years to come since we aim to meet and surpass all our clients’ expectations. Please don’t hesitate to contact us immediately if you have any queries regarding the equipment you require or how we may be of assistance.

--END--